Testing and Commissioning: Ultimate Assurance

Providing end-to-end services for Operational Technology, from concept to completion

Zealinx specializes in providing industrial automation solutions for operational technology, focusing on Testing and Commissioning to ensure every system operates flawlessly. We specialize in three key areas:

Control Device Programming

Our experts excel in developing and implementing control device programs that are specifically tailored to your unique requirements. Whether it's a programmable logic controller (PLC) or a numerical relay-IED, our Testing and Commissioning processes ensure the smooth operation and control of your facility. With our customized programming solutions, you can optimize the performance and functionality of your equipment, allowing for seamless operations.

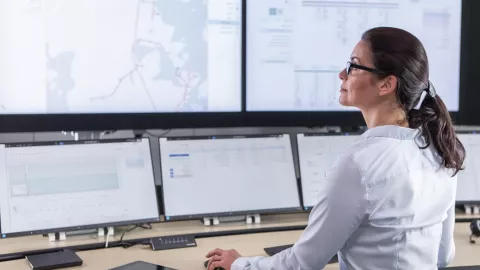

HMI Design & Implementation

We understand the importance of having a user-friendly and intuitive Human-Machine Interface (HMI) in your industrial setting. That’s why we offer Testing and Commissioning services alongside customized HMI design and implementation services. Our team will work closely with you to create a seamless interaction between humans and machines, resulting in improved productivity and reduced human error. With our expertise in HMI design, you can enhance the overall user experience and streamline operations within your facility.

SCADA System Integration

In today's interconnected world, it's crucial to have integrated systems that facilitate the smooth operation of various components within an industrial setting. Our team specializes in system integration, with a strong focus on Testing and Commissioning, allowing you to seamlessly connect different OT systems at your site. Whether it's integrating PLCs, HMIs, or other devices, we ensure that all components work together harmoniously, optimizing the overall performance of your facility.

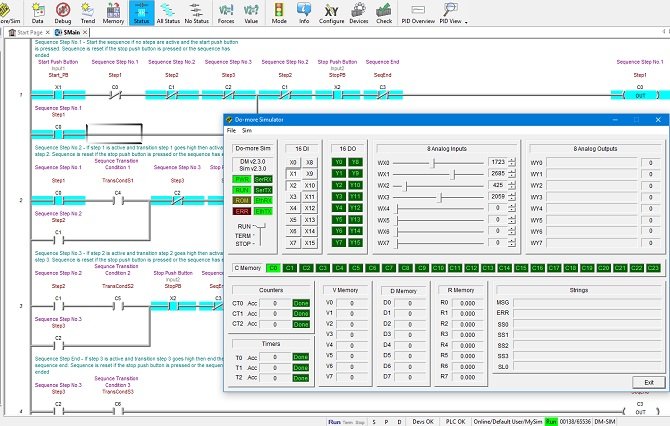

Control Device Programming

Programmable Logic Controllers (PLCs) are essential components in manufacturing and industrial automation. They function as industrial computers with multiple inputs and outputs, allowing engineers and technicians to efficiently control and monitor complex industrial processes. Our Testing and Commissioning services ensure these systems operate at peak efficiency. PLCs are particularly advantageous because their internal timers, sequencers, and relays operate at a much faster speed than conventional time-delay relay systems. This makes them highly suitable for effectively managing assembly lines.

The numerical relay configuration in substations is another critical aspect of industrial control systems where our Testing and Commissioning guarantees reliability and safety. Numerical relays act as protective devices, specifically designed to safeguard power systems such as generators, motors, transformers, and lines. Utilizing microprocessors, these relays determine various parameters such as power flow direction, fault presence, and fault type.

Both PLC programming in manufacturing and numerical relay configuration in substations play vital roles in ensuring efficient operations, protecting crucial equipment, and maintaining safety within industrial settings.

HMI Design & Implementation

Human Machine Interface (HMI) design and implementation is a critical aspect of industrial automation systems. It bridges the gap between operators and the automation system, allowing for efficient interaction and control. Our Testing and Commissioning process, begins by understanding the client's specific needs, the complexity of their processes, and their operational goals. This includes evaluating the current system, identifying areas for improvement, and defining the desired functionalities of the HMI. The HMI is designed with user-friendliness as a priority. ensuring that the design is intuitive, easy-to-navigate, and visually appealing. The design also takes into account safety standards and guidelines.

Team of engineers and technicians will then implement the HMI solution, integrating it with the existing PLCs and other components of the automation system. This could involve writing necessary scripts or codes, configuring the system, and testing to ensure everything works seamlessly. We provides comprehensive training to the operators, ensuring they can effectively use the HMI. This includes demonstrating how to monitor processes, adjust parameters, diagnose issues, and perform other tasks.

After implementation, ongoing support and maintenance services. This includes regular system checks, software updates, troubleshooting, and repairs as needed. The ultimate goal in HMI design and implementation service, supported by Testing and Commissioning is to enhance operational efficiency, reduce downtime, and improve safety in the client's facility.

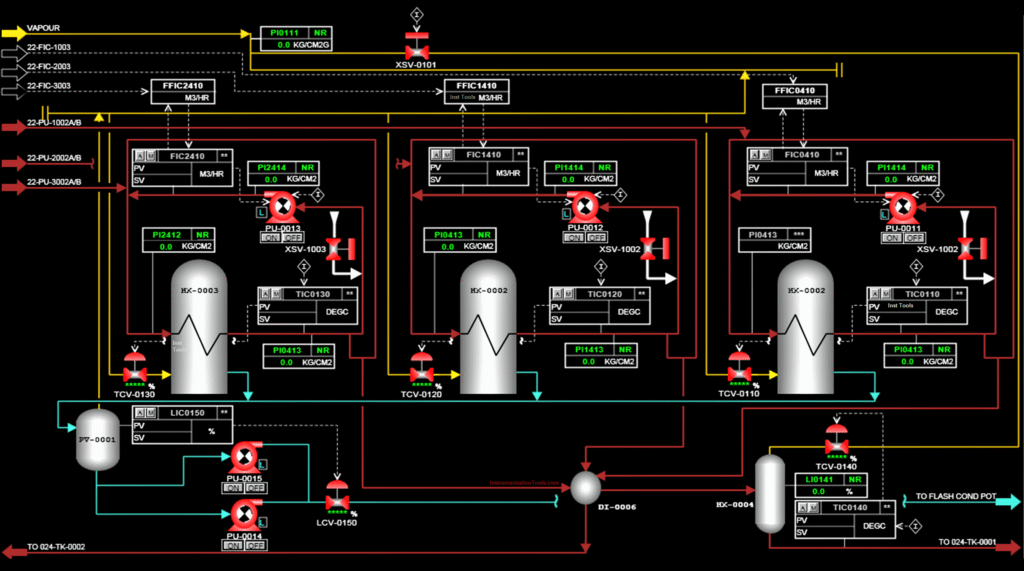

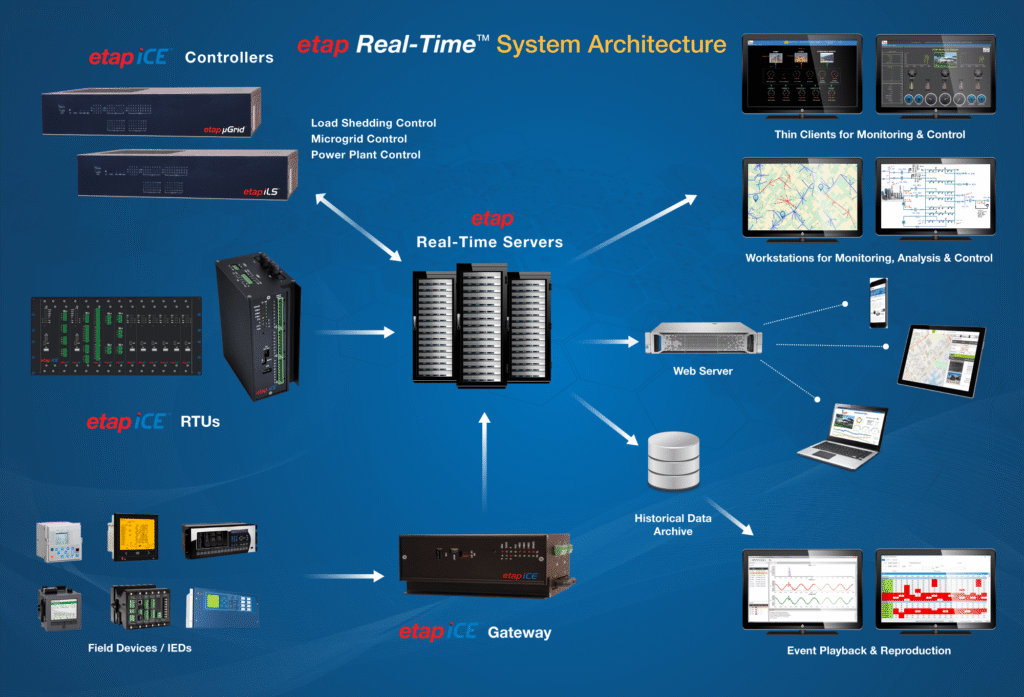

SCADA System Integration

SCADA and DCS are two types of industrial control systems used in various industries for process automation. SCADA systems are centralized and can monitor and control large areas or complex systems. They gather information, analyze it, and alert the necessary parties. Key components of a SCADA system include Human-Machine Interface, Remote Terminal Units, Programmable Logic Controller, and various communication methods.

On the other hand, DCS refers to a distributed control system where the controller elements are spread throughout the system. It is commonly used in industries like chemical plants and power generation. Key components of a DCS include input/output devices, controllers, networks, and operator stations.

Our solution ensures that maintenance personnel are promptly notified of critical alarms, even outside of working hours. This allows for unattended plant operations and substantial savings on labor costs for our customers. We have extensive experience with industry-leading vendors in areas such as communications network design, hardware and software specification, system design standards, and security policies and procedures.

Our expertise also extends to network cabinet, RTU, and control panel design and fabrication. In addition, we provide SCADA software configuration for tags, alarms, graphics, trends, and reports with seamless communication and integration with external systems. We also offer field Testing and Commissioning services, along with comprehensive training, to support our customers throughout the entire automation process.

By focusing on Testing and Commissioning, we ensure that all systems work together harmoniously, optimizing overall performance and reliability.

Boost efficiency and control with Zealinx

Our experts tailor control device programs to meet your unique needs, optimizing equipment performance for seamless operations. Boost productivity with our intuitive HMI design and Testing and Commissioning services, which reduce human error and enhance the user experience. Achieve system harmony with our specialized subsystem integration, connecting all OT components to optimize your facility's overall performance. Experience the power of seamless automation with Zealinx.

By choosing our industrial automation solutions, you can expect:

- Customized solutions that are tailored to your specific needs, ensuring optimal functionality and efficiency.

- Expert programming and Testing and Commissioning services that guarantee seamless operation and control of your equipment.

- User-friendly and intuitive interfaces that enhance productivity and minimize human error.

- Integrated systems that allow for smooth operation and communication between various components within your facility.

we are committed to providing top-notch industrial automation solutions that optimize the performance of your facility. With our expertise and dedication, we can help you streamline operations, boost productivity, and maximize efficiency. Trust us to take your industrial automation to the next level.

Act Now to Propel Your Business Forward

Don't let your business fall behind the curve. Harness the power of automation tools by choosing Zealinx.

Witness firsthand how our Testing and Commissioning services can revolutionize your operations and elevate your business to new heights. For more information or to request a consultation,

Remember, the sooner you invest in automation, the quicker you'll realize the benefits of increased reliability, availability, and safety in your operations.

Contact Us

Engineering, Testing & Commissioning

We provide comprehensive engineering, testing, and commissioning services tailored to the complex needs of the power & energy and oil & gas industries. Our expertise spans the full project lifecycle—from design consultation and system integration to field testing and final commissioning—ensuring that every system we touch is safe, reliable, and ready for operation.

At Zealinx, we specialize in delivering end-to-end engineering, testing, and commissioning solutions tailored to the critical demands of the power & energy and oil & gas sectors. With deep industry expertise, we manage the entire project lifecycle—from initial design and system integration to rigorous field testing and seamless commissioning. Our focus on safety, reliability, and compliance ensures every solution we deliver is operationally ready and built to perform under real-world conditions.

Overcoming Complex Commissioning Challenges

Tight timelines or complex commissioning requirements? Zealinx delivers streamlined, expert-driven support to ensure your systems go live safely, efficiently, and on schedule.

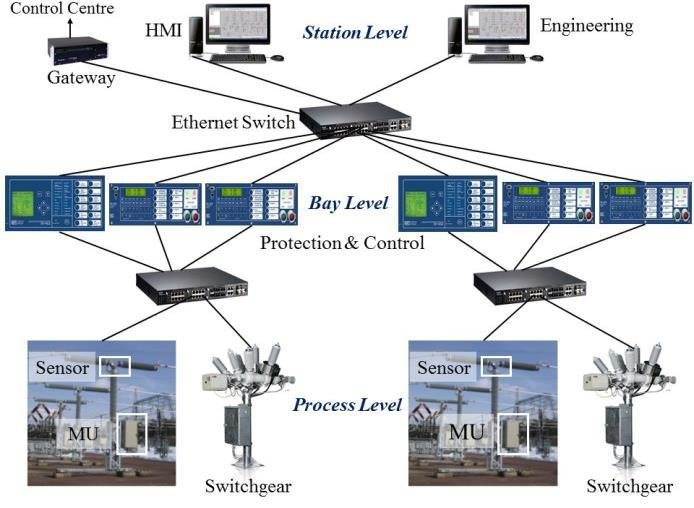

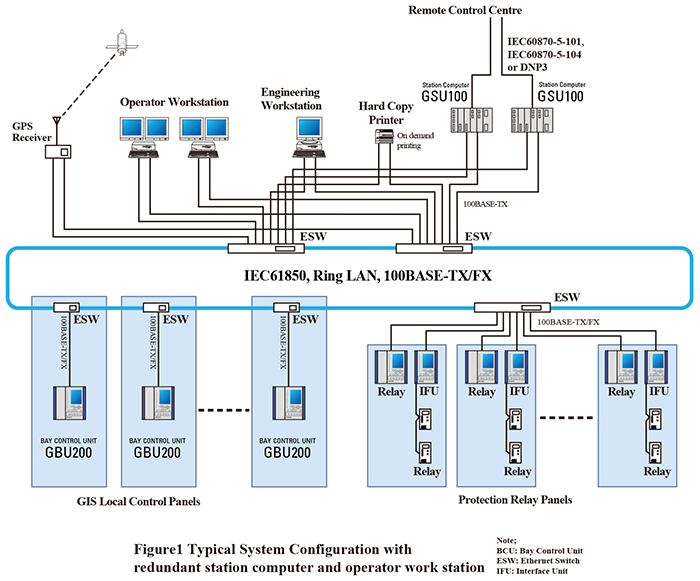

Substation Automation Systems (SAS) Integration

We provide expert integration of Substation Automation Systems using vendor-supplied IEDs and communication protocols. Our team ensures seamless interoperability between protection relays, bay control units, and SCADA systems. We handle configuration, parameterization, and testing of devices to ensure reliable data exchange and control. Whether it's a greenfield substation or a retrofit project, we ensure that the automation layer is robust, standards-compliant, and ready for grid synchronization.

Control Relay Panel (CRP) & Relay Testing

Our CRP services cover the full lifecycle—from procurement support and panel wiring verification to relay configuration and protection scheme validation. We perform relay setting calculations based on system studies and conduct secondary injection testing to verify protection logic. Our team ensures that all relays operate as intended under fault conditions, providing fast, accurate protection for critical assets.

SCADA System Design & Integration

We design SCADA systems that provide centralized monitoring and control of substations and industrial assets. Our services include architecture design, HMI development, protocol mapping (IEC 60870-5-104, DNP3, Modbus, etc.), and integration with dispatch centers. We ensure that the SCADA system is scalable, cyber-secure, and capable of real-time data acquisition, alarm management, and historical trending.

Remote Terminal Unit (RTU) Testing

We conduct comprehensive RTU testing to validate field device communication and control logic. This includes I/O point verification, protocol simulation, and end-to-end testing with SCADA systems. We ensure that RTUs are correctly configured, responsive, and capable of handling real-time data exchange with minimal latency or error.

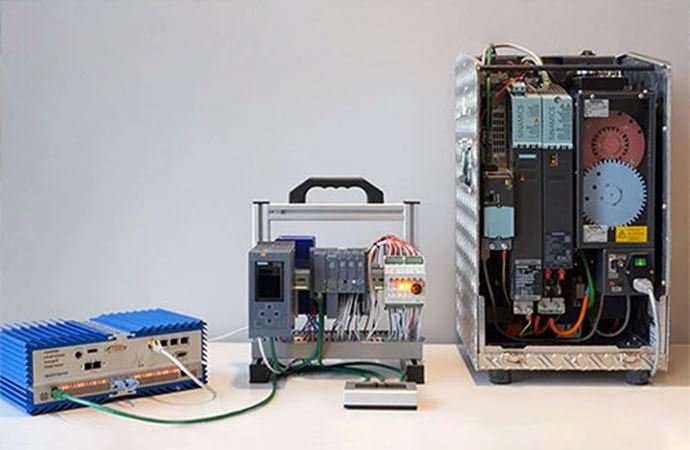

Programmable Logic Controller (PLC) Testing

Our PLC testing services ensure that automation logic is implemented correctly and safely. We verify ladder logic, function blocks, and interlocks, and simulate process conditions to validate system behavior. This is critical in oil & gas and industrial environments where PLCs control essential processes such as pumping, metering, and safety shutdown systems.

Engineering & Consultation Services

We support clients from concept to commissioning with:

Project Management & Electrical Consultation

Feasibility Studies, Site Assessments & Risk Analysis

Conceptual & Detailed Design (Electrical, Layout, Structural)

Procurement Management for CRP & SAS Panels

Relay Setting Calculations & Protection Coordination

CRP & SAS Panel Commissioning

SCADA/RTU Testing with Dispatch Centers

Site Acceptance Testing (SAT)

Documentation, Reporting & Punch Point Closure

Project Experience & Technical Expertise

We’ve successfully delivered complex infrastructure projects across Africa, including:

SCADA Projects

400/220/33kV Substation

Chimuara, Mozambique

220/110/33kV Substation

Old Chimuara, Mozambique

400/220/33kV Substation

Akoupe, Ivory Coast

Software:

Siemens Digsi 5

IED Configurator

PCM 2.10

Microscada Version 9.4 FP2

400/220/33kV Substation

Alto Molocue, Mozambique

Line Bay Integration

Kinsasha, Congo

IED’s integration:

Siemens 7SL85

Siemens 7SJ66

ABB REC670

ABB REL670

Cewe Prometer 100

Sicam 3000 MFM

and many more..

Why Zealinx

Trusted Across Borders and Industries

We’ve delivered high-impact projects across multiple countries and sectors.

Partnering with Top OEMs for Seamless Solutions

We work seamlessly with leading OEMs and technologies to ensure compatibility and performance.

Complete Lifecycle Management, Delivered Right

From design and procurement to testing and commissioning, we manage every detail with precision.

Engineered to Meet IEC, IEEE, and Utility Standards

All services are aligned with IEC, IEEE, and utility-specific standards.

Partnered for Scalable, Real-World Success

We collaborate closely with your team to deliver solutions that are practical, scalable, and aligned with your operational goals.

FREQUENTLY ASKED QUESTIONS

1. What types of control devices can Zealinx program for my facility?

Zealinx programs PLCs and numerical relay-IEDs, customizing solutions to optimize control and performance based on your specific needs.

2. How does Zealinx ensure the HMI is user-friendly?

We design intuitive HMIs tailored to your requirements and provide thorough training and ongoing support to ensure ease of use and effectiveness.

3. What is SCADA system integration, and how can Zealinx help?

SCADA system integration connects and optimizes various control systems, and Zeali ensures seamless integration for improved monitoring and control.

4. Can Zealinx assist with both new installations and upgrades?

Yes, Zeali handles both new installations and upgrades, offering services that include programming, HMI design, and SCADA integration.

5. What ongoing support does Zealinx provide?

We offer regular system checks, updates, troubleshooting, and repairs to ensure your systems remain efficient and operational over time.