Introduction

The manufacturing sector is undergoing a massive transformation with the rise of Industry 4.0 and the adoption of Industrial Internet of Things (IIoT) technologies. From predictive maintenance to real-time production monitoring, factories are becoming smarter, more connected, and highly data-driven.

But here’s the catch—without a reliable way to connect machines, gather data, and enable secure remote access, these advanced technologies can’t function effectively. This is where edge gateways come into play.

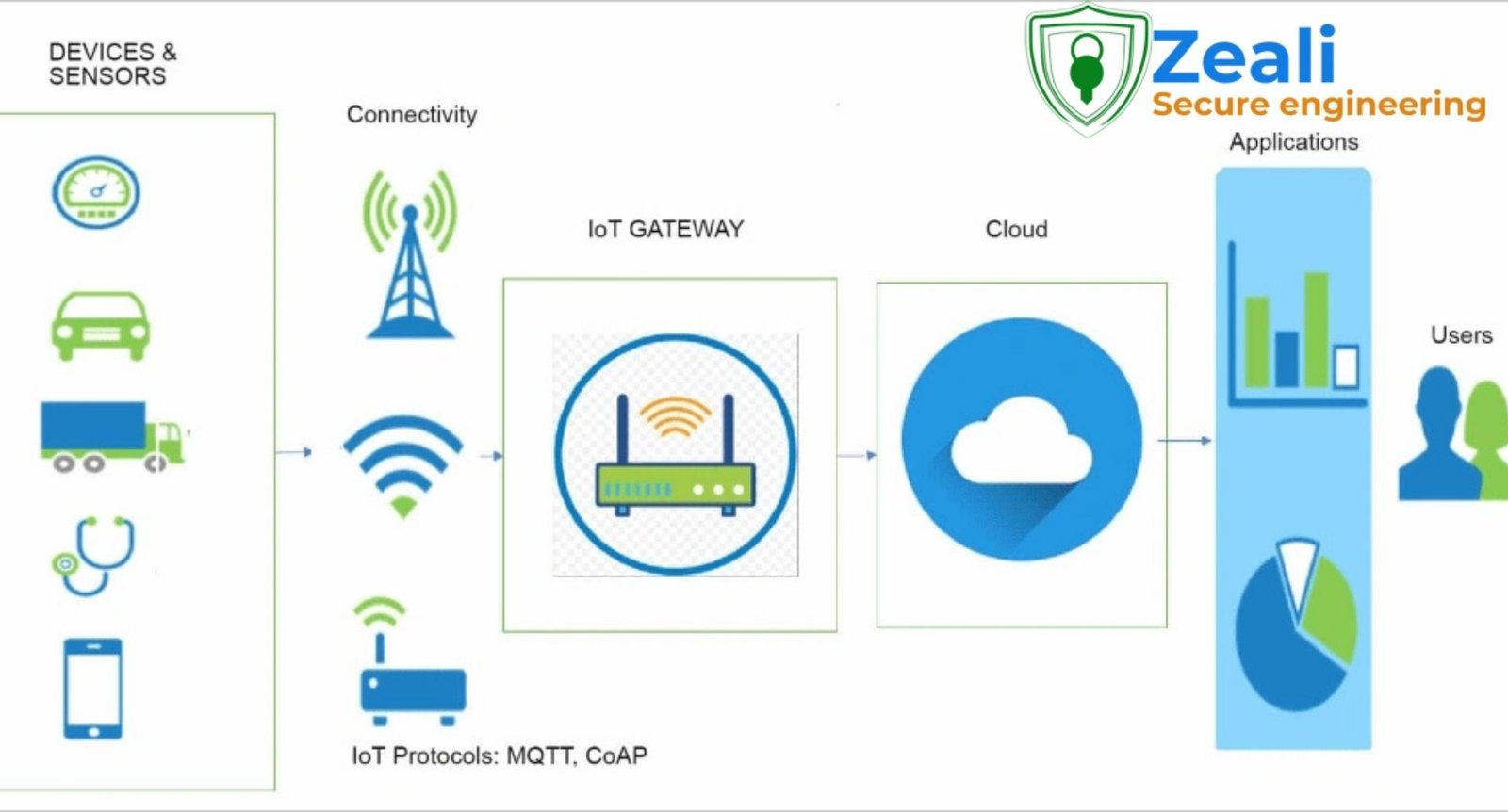

An edge gateway acts as the bridge between industrial machines and the digital world, enabling seamless data transfer, remote troubleshooting, and secure cloud connectivity.

What is an Edge Gateway?

To put it simply, an edge gateway is like the traffic controller of industrial data. It sits between your machines and the cloud, ensuring that data flows securely and efficiently. Unlike a standard router that just passes internet traffic, an edge gateway is smart—it processes, filters, and analyzes data locally before sending it to the cloud.

Here’s what an edge gateway typically does:

- Data Collection: Pulls machine data from PLCs, sensors, and controllers.

- Protocol Translation: Converts different machine languages (Modbus, OPC-UA, Siemens S7, etc.) into a unified format.

- Local Processing: Filters unnecessary data and processes critical information at the factory floor (the “edge”).

- Cloud Connectivity: Sends the right data to the cloud for analysis, dashboards, and AI-driven insights.

- Remote Access: Allows engineers to securely troubleshoot machines without being physically present.

In manufacturing, where even a few minutes of downtime can cost millions, an edge gateway ensures machines are monitored 24/7 and problems are resolved quickly.

Challenges in Manufacturing Connectivity

Understanding the Importance of Edge Gateways in Connectivity

Key Advantages of Using an Edge Gateway

Let’s talk about the common challenges manufacturers face with connectivity:

- Legacy Machine Integration

Many factories still run on decades-old machines that don’t support modern connectivity standards. Getting these machines online securely is a big challenge. - Data Security Concerns

Cyberattacks on industrial networks are on the rise. Without proper encryption and authentication, connecting machines to the cloud can be risky. - Downtime and Production Losses

If engineers can’t remotely access machines, every breakdown requires on-site visits—leading to longer downtime and higher costs. - Scalability Issues

Traditional networking solutions often fail when scaling up across multiple plants or global locations.

These challenges highlight why the right edge gateway is essential—and why the IXON Gateway has become a game-changer.

There are many options available, one solution stands out in the manufacturing sector: the IXON Gateway.

Known for its plug-and-play setup, high-level security, and integration with IXON Cloud, the IXON Gateway has become a trusted choice for manufacturers across industries. In this blog, we’ll explore why it’s considered the best edge gateway for manufacturing, what makes it unique, and how it’s reshaping industrial operations worldwide.

Why the IXON Gateway Stands Out

The IXON Gateway isn’t just another industrial device—it’s designed specifically with manufacturers and machine builders in mind.

Here’s why it stands out:

- Company Legacy: IXON is a global leader in IIoT solutions with a focus on secure, easy-to-use industrial connectivity.

- Plug-and-Play Setup: Unlike complex networking devices, the IXON Gateway is designed for engineers. No deep IT knowledge is required.

- Cloud + Edge Hybrid: Combines local edge processing with seamless cloud integration for the best of both worlds.

- Protocol Compatibility: Supports almost all major industrial protocols, making it easy to connect with legacy and modern machines.

- Future-Proof: Built with scalability and upcoming IIoT needs in mind.

The IXON Gateway serves as the vital link between machines, engineers, and intelligent, data-driven decision-making.

Key Features of the IXON Gateway

The IXON Edge Gateway comes packed with features tailored for modern manufacturing:

- Secure Remote Access

Engineers can log into machines from anywhere with VPN-level security, reducing the need for costly site visits. - IIoT Data Logging & Dashboards

The gateway collects and stores machine data, then displays it on customizable dashboards via the IXON Cloud. - Protocol Compatibility

It operates smoothly with leading industrial protocols such as Modbus, OPC-UA, Siemens S7, Ethernet/IP, and many others. - Plug-and-Play Setup

Designed for fast deployment, it connects easily without complex IT configurations. - Cloud-Edge Hybrid Model

Critical processing is handled locally (edge), while advanced analytics and monitoring happen in the cloud.

These features make the IXON Gateway not just a tool, but a complete solution for smart manufacturing.

IXON Gateway vs Traditional Gateways

When evaluating edge gateways for the manufacturing sector, it’s important to look beyond the basics. Traditional gateways, as well as well-known alternatives like eWON Cosy, Siemens Scalance, or Moxa devices, serve a role in connecting industrial machines to networks, but their capabilities differ significantly when compared to the IXON Edge Gateway.

Here’s how IXON Gateway compares:

| Feature | Traditional Gateways | IXON Edge Gateway |

| Remote Access | Limited or none | Secure VPN-level remote access |

| Protocol Support | Limited | Wide support (Modbus, OPC-UA, Siemens S7, etc.) |

| Cloud Integration | Requires add-ons | Native IXON Cloud connectivity |

| Data Logging | Minimal | Advanced IIoT logging & dashboards |

| Security | Basic | ISO-certified, encryption, MFA |

| Scalability | Difficult to expand | Easily scalable across sites |

Result? IXON Gateways deliver far more value, security, and flexibility than traditional alternatives—making them the better long-term investment.

Benefits of IXON Gateway in Manufacturing

Understanding the Role of Edge Gateways in Modern Manufacturing

The IXON Edge Gateway offers tangible benefits that directly address the pain points of the manufacturing industry. By combining secure connectivity with IIoT intelligence, it brings efficiency, productivity, and peace of mind to machine builders and plant operators.

- Reduced Downtime

Unplanned downtime is every manufacturer’s nightmare. With the IXON Gateway, engineers gain remote troubleshooting access, allowing them to diagnose and fix machine issues without waiting for travel or on-site support. This means production lines are back up and running faster, saving both time and revenue.

- Predictive Maintenance

The gateway enables data-driven insights by continuously logging machine performance data. With this, factories can predict failures before they happen and schedule maintenance proactively. This shifts operations from reactive repairs to predictive maintenance, significantly improving machine uptime.

Traditional remote access solutions are often risky. IXON’s gateway provides VPN-level encryption, two-factor authentication, and ISO-certified security standards, ensuring that only authorized personnel can access sensitive machine data.

- Cost Efficiency

By eliminating the need for constant site visits and reducing production stoppages, manufacturers see a rapid return on investment (ROI). Compared to legacy connectivity setups, IXON delivers long-term savings while adding modern IoT features.

In short, IXON transforms industrial plants from reactive, isolated systems into proactive, connected ecosystems.

Security Standards in IXON Gateway

Security is no longer optional in manufacturing—it’s a must-have. With cyberattacks on industrial facilities rising, the IXON Gateway has been designed with security-first principles.

Here’s how IXON ensures safety:

- End-to-End Encryption: All machine data is encrypted in transit and storage.

- ISO/IEC Certified Security: IXON complies with international security standards.

- Two-Factor Authentication: Extra login protection prevents unauthorized access.

- Firewall-Friendly Setup: Works securely behind corporate firewalls without needing complex IT configurations.

This security framework gives plant managers confidence that their machines and data remain safe, even when accessed remotely.

Use Cases of IXON Gateway in Industry

The beauty of the IXON Gateway is its versatility. It fits into multiple industries with ease, thanks to its wide protocol compatibility and edge-cloud hybrid model. Let’s explore some real-world applications:

- Automotive Manufacturing

Factories that build vehicles rely heavily on robotics and precision systems. The IXON Gateway ensures that these machines are monitored in real-time, allowing predictive analytics to prevent costly assembly line halts.

- Food & Beverage Industry

With strict hygiene standards and round-the-clock operations, food processing plants use IXON to monitor temperature, machine health, and compliance data. Engineers can troubleshoot remotely to avoid contamination risks caused by downtime.

- Pharmaceutical Sector

Drug manufacturing demands high accuracy and strict regulatory compliance. IXON Gateways securely log process data, which is crucial for audits and ensures that machines remain compliant with GMP standards.

- Heavy Machinery & Equipment

In industries like mining, construction, and oil & gas, machines are often located in remote or hazardous areas. With IXON Gateways, operators can monitor performance remotely, reducing risks and minimizing site visits.

These use cases highlight the IXON Gateway as an all-rounder solution for industrial IoT.

Customer Success Stories

Nothing shows IXON’s power better than its success in real-world operations.

Case Study 1 – Reducing Downtime by 30%

With projects spanning across the globe, they need a smarter way to manage equipment. By integrating the IXON Edge Gateway router, they achieved real-time remote monitoring, predictive maintenance, and faster troubleshooting. The result? 30% less downtime, lower service costs, and happier clients worldwide.

Case Study 2 – Driving Machine Uptime

As a leader in textile machinery, they wanted to enhance machine connectivity and customer support. Our IXON Edge Gateway routers enabled secure IIoT connectivity, remote diagnostics, and cloud-based monitoring. This upgrade helped them to deliver quicker service, higher machine uptime, and stronger customer trust.

Future of Edge Gateways in Manufacturing

As we move further into Industry 4.0 and Industry 5.0, edge gateways will play a central role in enabling smarter, more autonomous factories.

Future trends with IXON Gateways:

- AI and Machine Learning at the Edge: Local gateways will analyze data instantly to make decisions without cloud dependency.

- Integration with Digital Twins: IXON will enable virtual replicas of machines for real-time monitoring and simulation.

- Sustainability Monitoring: Gateways will help optimize energy use, reduce waste, and support greener manufacturing.

Clearly, IXON is positioned as a future-ready solution for evolving industrial demands.

Conclusion

The manufacturing sector is evolving rapidly, and connectivity is no longer optional—it’s a necessity. The IXON Edge Gateway stands out as the best solution for industrial IoT in manufacturing thanks to its:

- Secure and reliable remote access

- Advanced IIoT data logging and cloud integration

- Wide compatibility with industrial protocols

- Easy deployment and scalability

By choosing IXON, manufacturers gain not only connectivity and security but also a clear path toward smart, future-proof factories.

FAQs

- What is an edge gateway in simple terms?

An edge gateway is a device that connects industrial machines to the internet or cloud, enabling data transfer, remote access, and local processing. It acts as the bridge between your factory floor and digital systems. - Can IXON Gateway work with legacy machines?

Yes. IXON supports multiple industrial protocols like Modbus, Siemens S7, and OPC-UA, making it compatible with both modern and legacy machines. - Is IXON Gateway suitable for small factories?

Absolutely. Its plug-and-play setup makes it ideal for small and medium manufacturers, while its scalability ensures it can also support large, multi-site enterprises. - How secure is the IXON Cloud?

The IXON Cloud is built with ISO/IEC-certified security standards, end-to-end encryption, and multi-factor authentication, ensuring maximum protection for industrial data. - Which industries benefit most from IXON Gateways?

IXON Gateways are widely used in automotive, food & beverage, pharmaceuticals, packaging, and heavy machinery sectors—basically, any industry that values uptime, efficiency, and secure connectivity.